Somos um dos maiores fabricantes de cilindros corrugadores e

peças para as indústrias de papelão ondulado da

América Latina.

Desde 1980, nossa empresa se destaca no mercado pela inovação, qualidade e confiabilidade na produção de cilindros corrugadores. Nosso prestígio se estende internacionalmente.

Seguimos rigorosos padrões e controle de qualidade, em todos os processos. Valorizamos cada detalhe e adaptamos nosso processo para atender às necessidades individuais de nossos clientes. Cumprir os prazos acordados é uma prioridade para nós.

Investimos constantemente em pesquisas e tecnologia em nossa linha de produção, resultado de quatro décadas de experiência. Nossos colaboradores são atualizados constantemente.

Nosso compromisso é proporcionar aos clientes aumento de produtividade, qualidade e competitividade. Somos reconhecidos pela qualidade desde o pedido até a entrega. Garantimos excelência nos processos de usinagem, tratamento térmico, revestimentos, retífica e muito mais.

Estamos prontos para superar suas expectativas, agregar valor e impulsionar o sucesso do seu negócio.

Somos um dos maiores fabricantes de cilindros corrugadores e

peças para as indústrias de papelão ondulado da

América Latina.

Desde 1980, nossa empresa se destaca no mercado pela inovação, qualidade e confiabilidade na produção de cilindros corrugadores. Nosso prestígio se estende internacionalmente.

Seguimos rigorosos padrões e controle de qualidade, em todos os processos. Valorizamos cada detalhe e adaptamos nosso processo para atender às necessidades individuais de nossos clientes. Cumprir os prazos acordados é uma prioridade para nós.

Investimos constantemente em pesquisas e tecnologia em nossa linha de produção, resultado de quatro décadas de experiência. Nossos colaboradores são atualizados constantemente.

Nosso compromisso é proporcionar aos clientes aumento de produtividade, qualidade e competitividade. Somos reconhecidos pela qualidade desde o pedido até a entrega. Garantimos excelência nos processos de usinagem, tratamento térmico, revestimentos, retífica e muito mais.

Estamos prontos para superar suas expectativas, agregar valor e impulsionar o sucesso do seu negócio.

Tecnologia

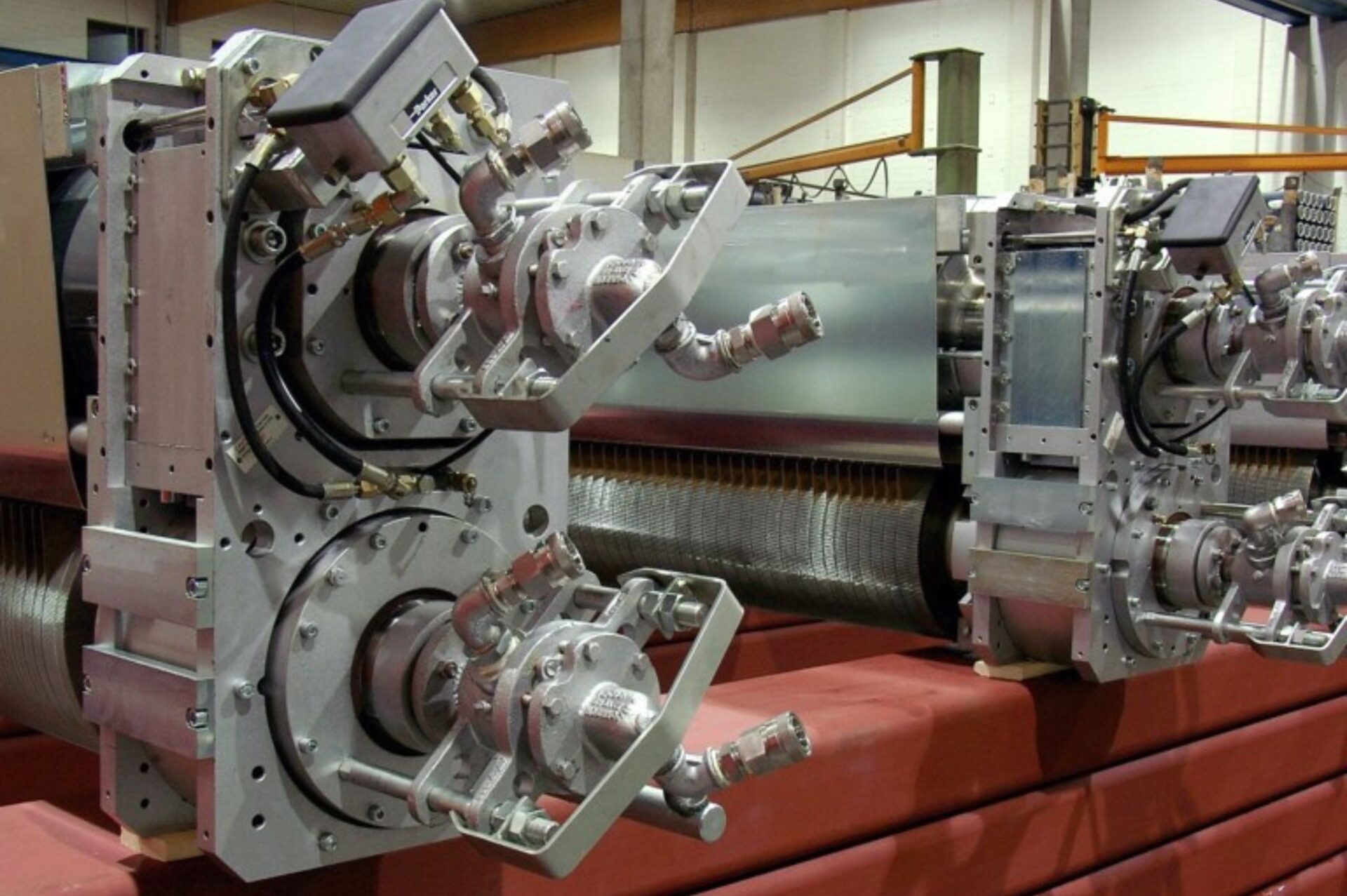

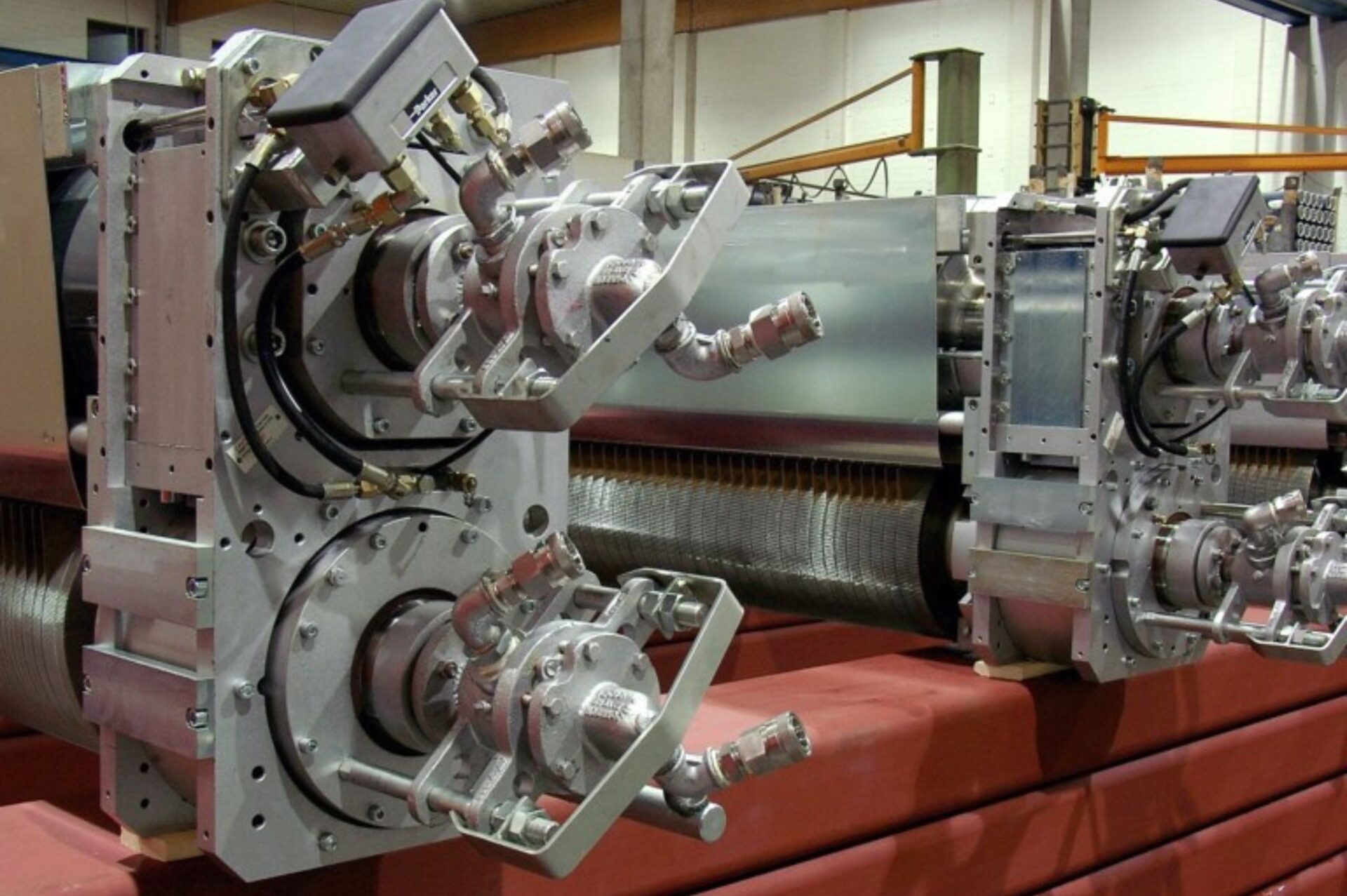

Os rolos corrugados Friese são fabricados inteiramente em nossas instalações, produzidos em equipamentos e recursos de última geração, sob processos controlados que garantem o cumprimento dos prazos assumidos, repetibilidade de processo e o mais alto nível de qualidade disponível no mercado.

- Retificadora CNC Waldrich Coburg especial para formação de ondas

- Tornos CNC programados para usinagem de pontas de eixo e acabamento dos rolos;

- Retífica cilíndrica Waldrich para acabamento de cilindros de pressão;

- Instalações de tratamento térmico (tempera por indução e fornos de nitretação);

- Instalações de revestimento superficial (aplicação do Rockwelle);

- Balanceadora

- Estação de soldagem

- Laboratório com instrumentos e equipamentos para controle e ensaios não destrutivos

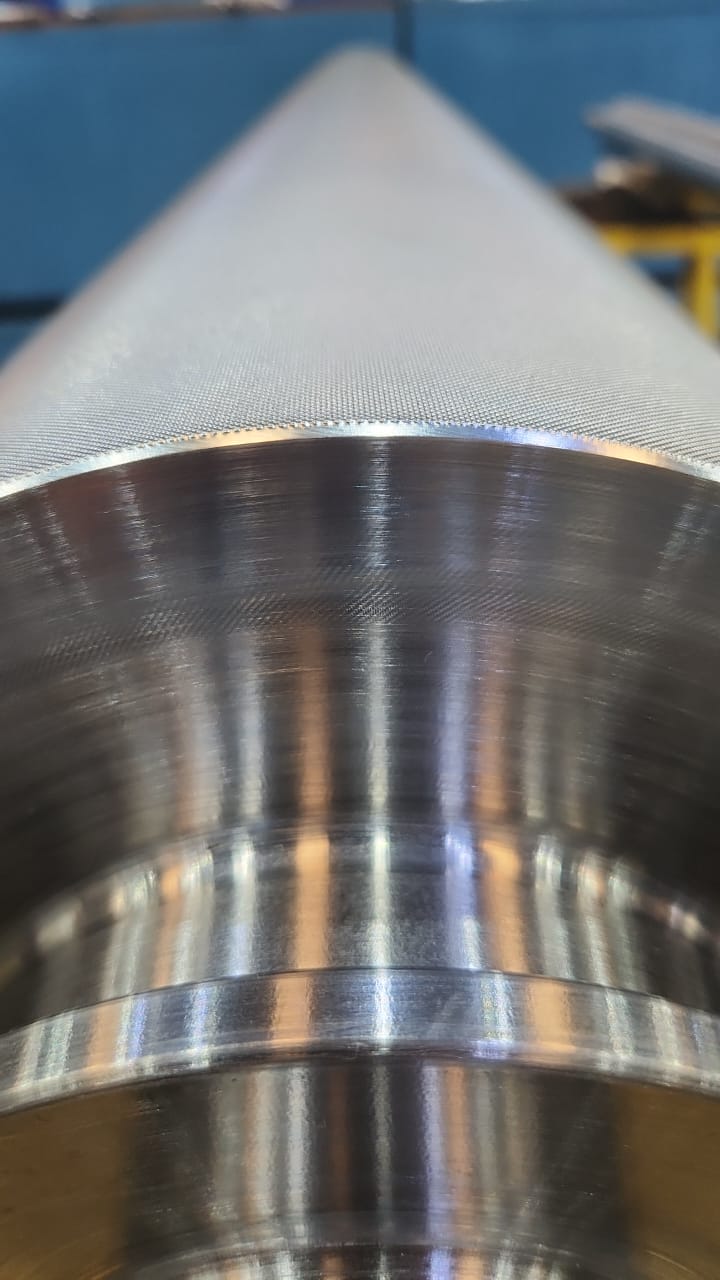

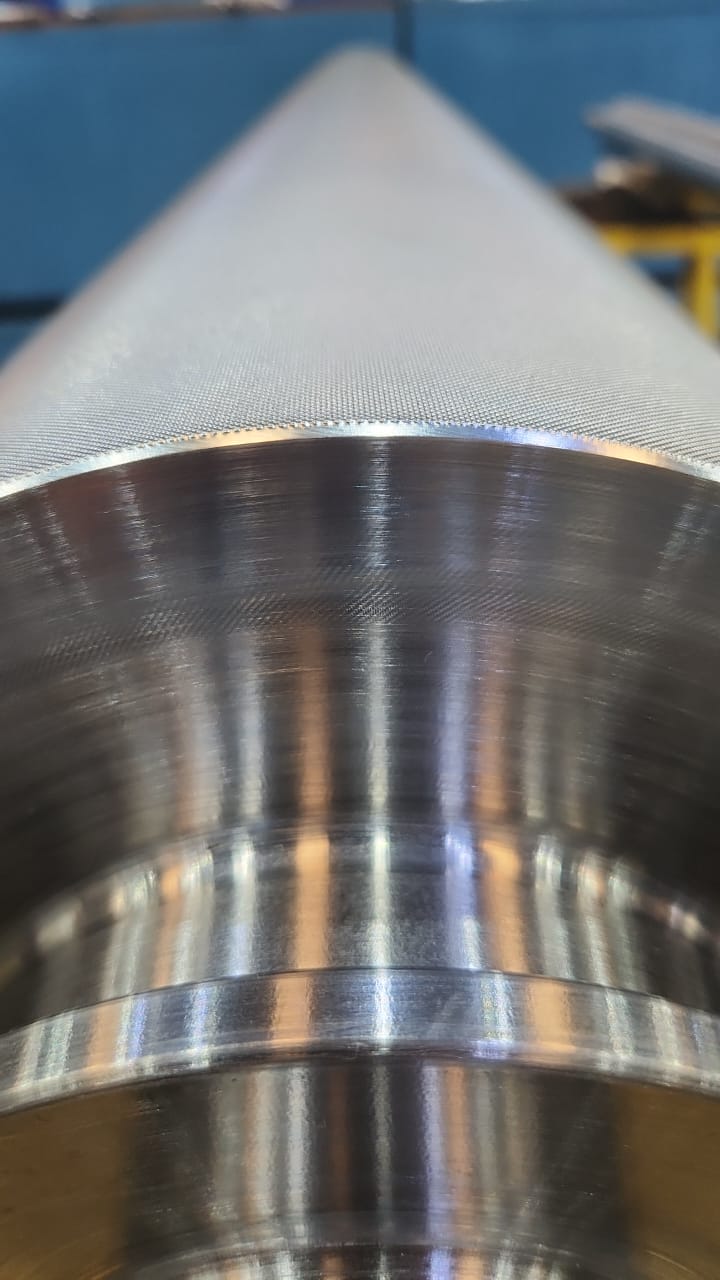

Os rolos corrugadores Friese são polidos nas máquinas mais modernas disponíveis, com a precisão requerida para a aplicação. Devido ao controle numérico computadorizado em nossos equipamentos, operamos com cilindricidade de 10 µm.

Vantagens de nossa tecnologia:

- Vida útil prolongada dos rolos

- Alta estabilidade do perfil

- Redução do consumo de papel de 2 a 5%

- Aumento da resistência da placa corrugadora em até 10%

- Baixo custo de manutenção e serviços

- Perfis projetados para aumento dos testes físicos nas chapas de papelão ondulado

- Produção contínua em níveis superiores de operação:

- Alta velocidade útil da produção

- Redução acentuada de vibrações

- Níveis de refugos reduzidos

Os rolos corrugados Friese são fabricados inteiramente em nossas instalações, produzidos em equipamentos e recursos de última geração, sob processos controlados que garantem o cumprimento dos prazos assumidos, repetibilidade de processo e o mais alto nível de qualidade disponível no mercado.

- Retificadora CNC Waldrich Coburg especial para formação de ondas

- Tornos CNC programados para usinagem de pontas de eixo e acabamento dos rolos;

- Retífica cilíndrica Waldrich para acabamento de cilindros de pressão;

- Instalações de tratamento térmico (tempera por indução e fornos de nitretação);

- Instalações de revestimento superficial (aplicação do Rockwelle);

- Balanceadora

- Estação de soldagem

- Laboratório com instrumentos e equipamentos para controle e ensaios não destrutivos

Os rolos corrugadores Friese são polidos nas máquinas mais modernas disponíveis, com a precisão requerida para a aplicação. Devido ao controle numérico computadorizado em nossos equipamentos, operamos com cilindricidade de 10 µm.

Vantagens de nossa tecnologia:

- Vida útil prolongada dos rolos

- Alta estabilidade do perfil

- Redução do consumo de papel de 2 a 5%

- Aumento da resistência da placa corrugadora em até 10%

- Baixo custo de manutenção e serviços

- Perfis projetados para aumento dos testes físicos nas chapas de papelão ondulado

- Produção contínua em níveis superiores de operação:

- Alta velocidade útil da produção

- Redução acentuada de vibrações

- Níveis de refugos reduzidos

Produtos

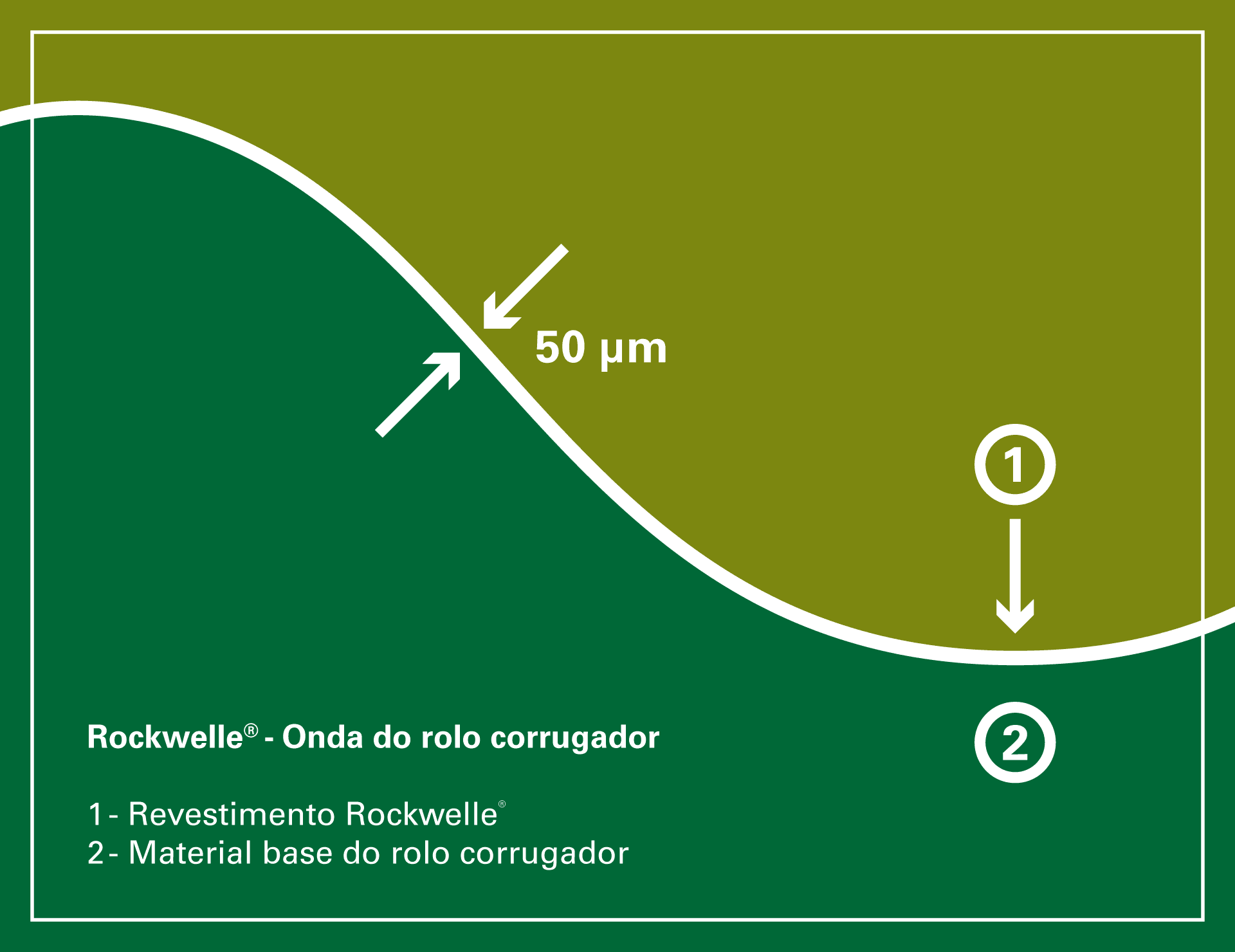

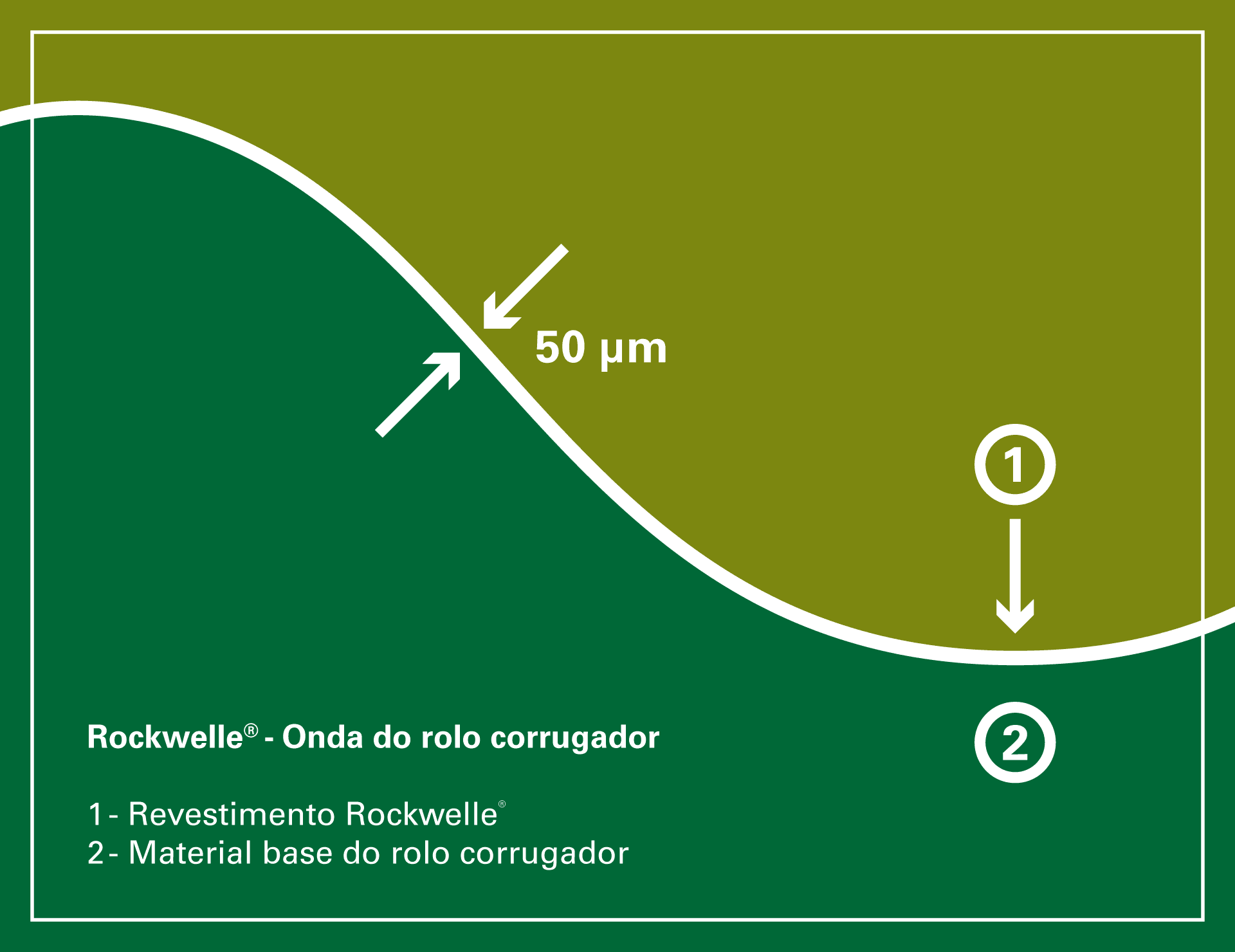

Em 1996, a Friese desenvolveu e introduziu o revestimento de carboneto de tungstênio, chamado de ROCKWELLE®. Com ele podemos oferecer soluções singulares em rolos corrugados, com geometria otimizada que entrega melhor performance em consumo de papel (menor take up) e testes físicos, desde um princípio até o final de vida dos rolos. Desde os processos de fabricação até a composição do revestimento, o ROCKWELLE® entrega uma qualidade extremamente distinta do mercado.

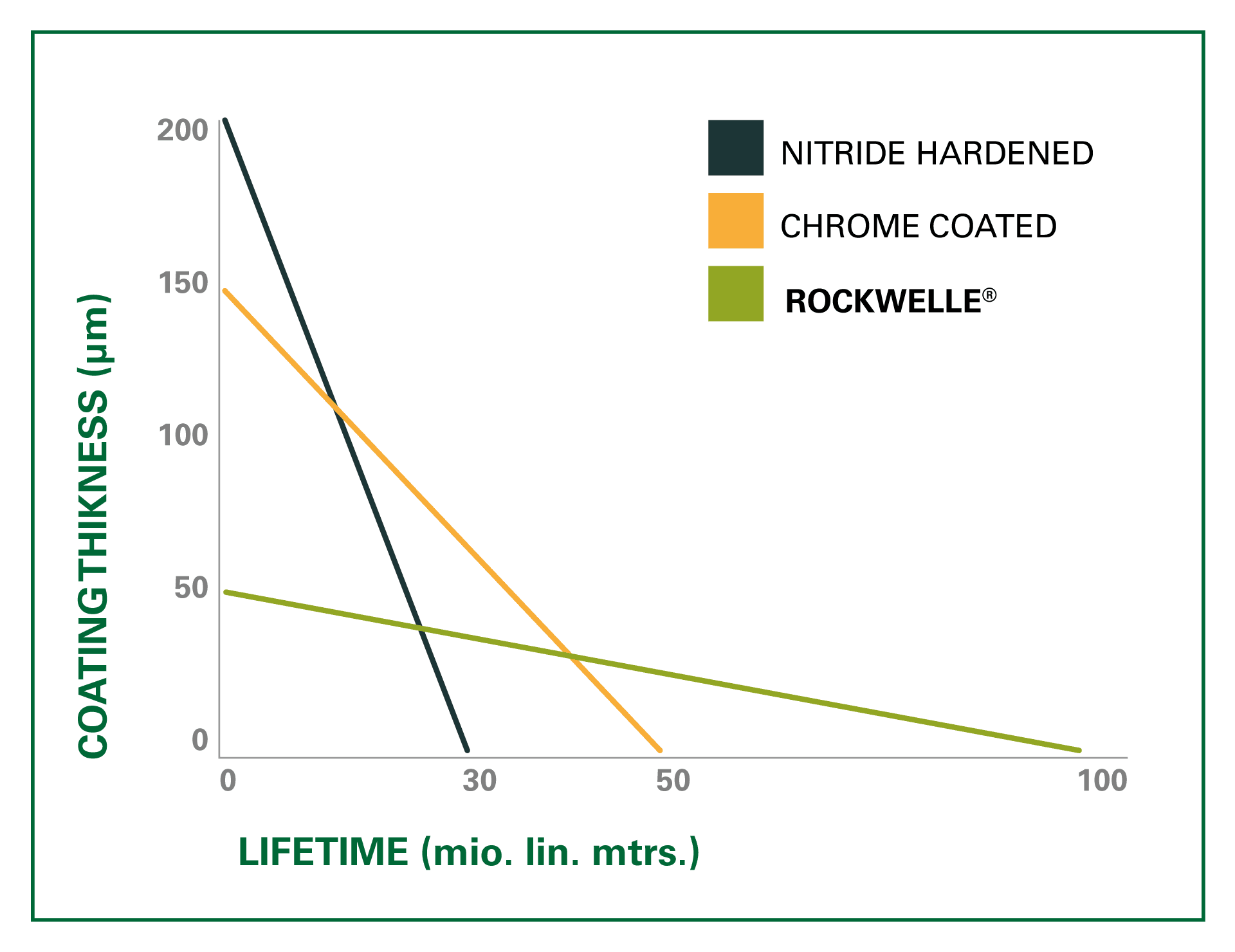

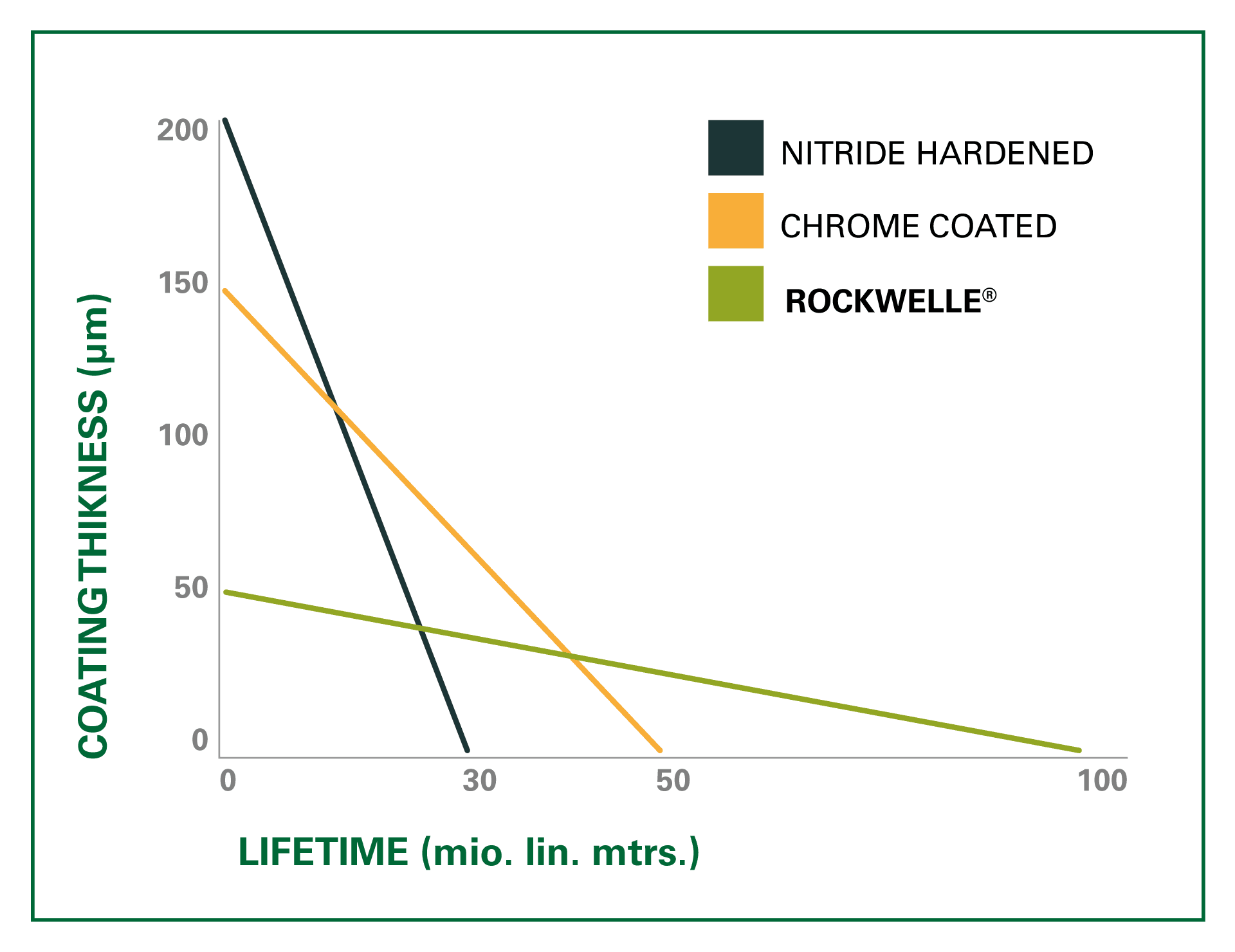

Comparado aos rolos endurecidos pelo processo de nitretação, ou aos revestidos de cromo, o ROCKWELLE® apresenta vida útil muito maior. Temos um processo de polimento de três etapas que garante baixa rugosidade da superfície, em comparação ao revestimento de cromo (aspereza Ra < 0,30 µm).

O desenvolvimento do revestimento permitiu a redução do custo de rolos corrugadores por metro linear em até 75%, ou seja, ROCKWELLE® oferece uma maior vida útil e custo-benefício.

O gráfico abaixo e à direita mostra a espessura do revestimento e a vida útil de diferentes superfícies de rolos corrugadores. Comparando com os rolos endurecidos por nitretação e revestidos com cromo, o Rockwelle® mostra uma vida útil muito mais elevada, praticamente sem nenhum desgaste perceptível nas laterais das ondas, garantindo a melhor performance do produto acabado, durante toda a vida do rolo.

O fato do perfil dos rolos com revestimento ROCKWELLE permanecer praticamente uniforme durante sua vida útil permite a otimização dos perfis de modo significativo. O resultado é o nosso ROCKPROFILE.

O ponto inicial para a otimização está na tensão minimizada no labirinto entre os rolos durante o processo de formação do papelão ondulado. Desta forma, é possível alcançar uma qualidade constante e superiores resultados de performance da chapa de papelão ondulado, ou seja, racionaliza-se por completo a operação com menores consumos de papel miolo e ganhos de testes.

O ROCKPROFILE é desenvolvido exclusivamente para cada aplicação. Os parâmetros individuais são considerados, como o tipo de Single Facer utilizado, o nível de qualidade do papel utilizado, a velocidade de produção e a aplicação da caixa de papelão. Dessa forma, a proporção de consumo de papel-miolo pode ser reduzida de modo significativo, e ainda proporcionar uma melhor resistência da chapa de papelão ondulado, se assim desejar o cliente.

A Friese utiliza tecnologia avançada para produzir vincos precisos e duráveis, atendendo aos mais altos padrões de qualidade. Um vinco bem fabricado é crucial para garantir a qualidade do acabamento da chapa de papelão, sua resistência estrutural, a precisão dimensional, a eficiência na produção, a redução de retrabalho e desperdício, e a facilidade de montagem em uma vincadeira.

Além disso, oferecemos suporte técnico e personalização de soluções. Escolher a Friese significa escolher confiabilidade, eficiência e excelência na fabricação de vincos novos.”

A Friese fabrica os cilindros dosadores e aplicadores de cola. Nossa equipe de engenheiros e técnicos experientes projeta e fabrica cilindros de alta qualidade para uma ampla gama de cabeçotes.

Os cilindros Friese são fabricados com os melhores materiais e equipamentos disponíveis, e são testados rigorosamente para garantir a qualidade e o desempenho. Também oferecemos uma ampla gama de acessórios e serviços para ajudar nossos clientes a obter o máximo de seus cilindros.

Fabricamos cassetes de rolos corrugados para vários modelos de cabeçotes. Consulte nos para mais informações.

- Rolos Corrugadores Temperados;

- Cilindros de Pressão;

- Rolamentos e Acessórios.

Em 1996, a Friese desenvolveu e introduziu o revestimento de carboneto de tungstênio, chamado de ROCKWELLE®. Com ele podemos oferecer soluções singulares em rolos corrugados, com geometria otimizada que entrega melhor performance em consumo de papel (menor take up) e testes físicos, desde um princípio até o final de vida dos rolos. Desde os processos de fabricação até a composição do revestimento, o ROCKWELLE® entrega uma qualidade extremamente distinta do mercado.

Comparado aos rolos endurecidos pelo processo de nitretação, ou aos revestidos de cromo, o ROCKWELLE® apresenta vida útil muito maior. Temos um processo de polimento de três etapas que garante baixa rugosidade da superfície, em comparação ao revestimento de cromo (aspereza Ra < 0,30 µm).

O desenvolvimento do revestimento permitiu a redução do custo de rolos corrugadores por metro linear em até 75%, ou seja, ROCKWELLE® oferece uma maior vida útil e custo-benefício.

O gráfico abaixo e à direita mostra a espessura do revestimento e a vida útil de diferentes superfícies de rolos corrugadores. Comparando com os rolos endurecidos por nitretação e revestidos com cromo, o Rockwelle® mostra uma vida útil muito mais elevada, praticamente sem nenhum desgaste perceptível nas laterais das ondas, garantindo a melhor performance do produto acabado, durante toda a vida do rolo.

O fato do perfil dos rolos com revestimento ROCKWELLE permanecer praticamente uniforme durante sua vida útil permite a otimização dos perfis de modo significativo. O resultado é o nosso ROCKPROFILE.

O ponto inicial para a otimização está na tensão minimizada no labirinto entre os rolos durante o processo de formação do papelão ondulado. Desta forma, é possível alcançar uma qualidade constante e superiores resultados de performance da chapa de papelão ondulado, ou seja, racionaliza-se por completo a operação com menores consumos de papel miolo e ganhos de testes.

O ROCKPROFILE é desenvolvido exclusivamente para cada aplicação. Os parâmetros individuais são considerados, como o tipo de Single Facer utilizado, o nível de qualidade do papel utilizado, a velocidade de produção e a aplicação da caixa de papelão. Dessa forma, a proporção de consumo de papel-miolo pode ser reduzida de modo significativo, e ainda proporcionar uma melhor resistência da chapa de papelão ondulado, se assim desejar o cliente.

A Friese utiliza tecnologia avançada para produzir vincos precisos e duráveis, atendendo aos mais altos padrões de qualidade. Um vinco bem fabricado é crucial para garantir a qualidade do acabamento da chapa de papelão, sua resistência estrutural, a precisão dimensional, a eficiência na produção, a redução de retrabalho e desperdício, e a facilidade de montagem em uma vincadeira.

Além disso, oferecemos suporte técnico e personalização de soluções. Escolher a Friese significa escolher confiabilidade, eficiência e excelência na fabricação de vincos novos.”

A Friese fabrica os cilindros dosadores e aplicadores de cola. Nossa equipe de engenheiros e técnicos experientes projeta e fabrica cilindros de alta qualidade para uma ampla gama de cabeçotes.

Os cilindros Friese são fabricados com os melhores materiais e equipamentos disponíveis, e são testados rigorosamente para garantir a qualidade e o desempenho. Também oferecemos uma ampla gama de acessórios e serviços para ajudar nossos clientes a obter o máximo de seus cilindros.

Fabricamos cassetes de rolos corrugados para vários modelos de cabeçotes. Consulte nos para mais informações.

- Rolos Corrugadores Temperados;

- Cilindros de Pressão;

- Rolamentos e Acessórios.

Serviços

Na Friese, o processo de retífica para a recuperação de rolos corrugadores é executado com o método “monoflute”, exclusivo da máquina Waldrich.

Projeto específico e exclusivo, considerando as novas dimensões de diâmetro dos rolos corrugadores desgastados para manter as características de geometria dos perfis originais, de forma a assegurar as mesmas condições dos rolos novos quanto a sua eficiência, consumo de papel (take-up) e vida útil.

Todo processo de retífica reduz o diâmetro dos rolos. O processo de retífica desenvolvido pela Friese, reduz ao mínimo, o desgaste nos diâmetros dos rolos, aumentando o número de retíficas.

A aplicação de Carbeto de Tungstênio nos vincos é uma tecnologia inovadora que oferece maior durabilidade e qualidade.

Esse material resistente ao desgaste e de alta precisão aumenta a vida útil dos vincos e melhora a conformação das chapas.

Com revestimentos avançados, essa tecnologia reduz os custos de substituição dos vincos, aumenta a eficiência da produção e garante produtos finais de alta qualidade.

- Montagem dos Rolos Corrugadores nos Cassetes;

- Montagem de Rolamentos e Acessórios;

- Acompanhamento de Instalação e Start-up;

- Suporte à Análise de Problemas nos Clientes;

- Otimização da geometria dos perfis.

Na Friese, o processo de retífica para a recuperação de rolos corrugadores é executado com o método “monoflute”, exclusivo da máquina Waldrich.

Projeto específico e exclusivo, considerando as novas dimensões de diâmetro dos rolos corrugadores desgastados para manter as características de geometria dos perfis originais, de forma a assegurar as mesmas condições dos rolos novos quanto a sua eficiência, consumo de papel (take-up) e vida útil.

Todo processo de retífica reduz o diâmetro dos rolos. O processo de retífica desenvolvido pela Friese, reduz ao mínimo, o desgaste nos diâmetros dos rolos, aumentando o número de retíficas.

A aplicação de Carbeto de Tungstênio nos vincos é uma tecnologia inovadora que oferece maior durabilidade e qualidade.

Esse material resistente ao desgaste e de alta precisão aumenta a vida útil dos vincos e melhora a conformação das chapas.

Com revestimentos avançados, essa tecnologia reduz os custos de substituição dos vincos, aumenta a eficiência da produção e garante produtos finais de alta qualidade.

- Montagem dos Rolos Corrugadores nos Cassetes;

- Montagem de Rolamentos e Acessórios;

- Acompanhamento de Instalação e Start-up;

- Suporte à Análise de Problemas nos Clientes;

- Otimização da geometria dos perfis.

Fale Conosco

Entre em contato conosco pelos contatos abaixo ou envie uma mensagem pelo formulário.

-

Rua Pierre Lafage, 252

Vl. Industrial Jaraguá, São Paulo - SP, 05163-060 - +55 11 3908-8800

- friese@friese.com.br